Three-phase power supply

Installed power 45kW

Estimated hourly output* BASED ON THE MATERIAL

Diameter of die hole** Usually 6 mm

Die diameter 398 mm (useful working diameter 360 mm)

Roller diameter N° 2 rollers diameter 180 mm

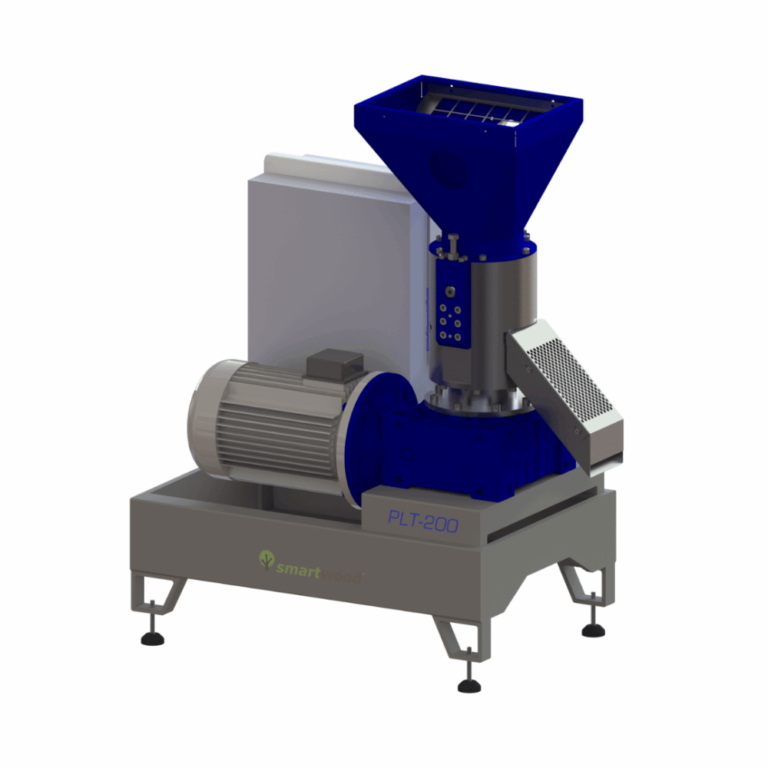

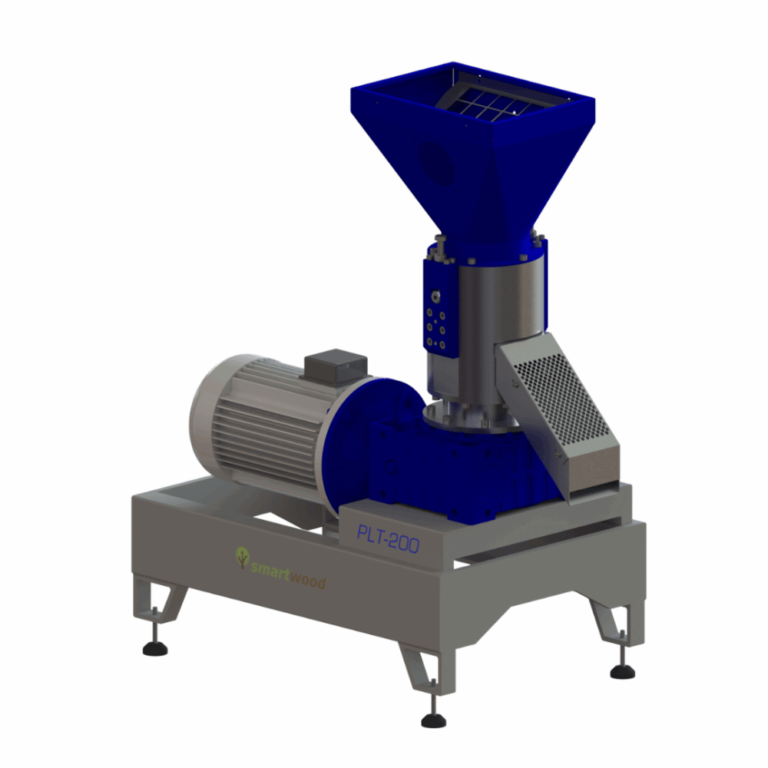

Dimensions (WxDxH) 181 x 96 x 152 cm

Weight 950 kg

The hourly output of the machines varies considerably depending on the type of biomass used. The data estimated in this catalogue are purely indicative and are therefore not binding in any way.

** The diameter of the die hole may vary according to customer requirements.

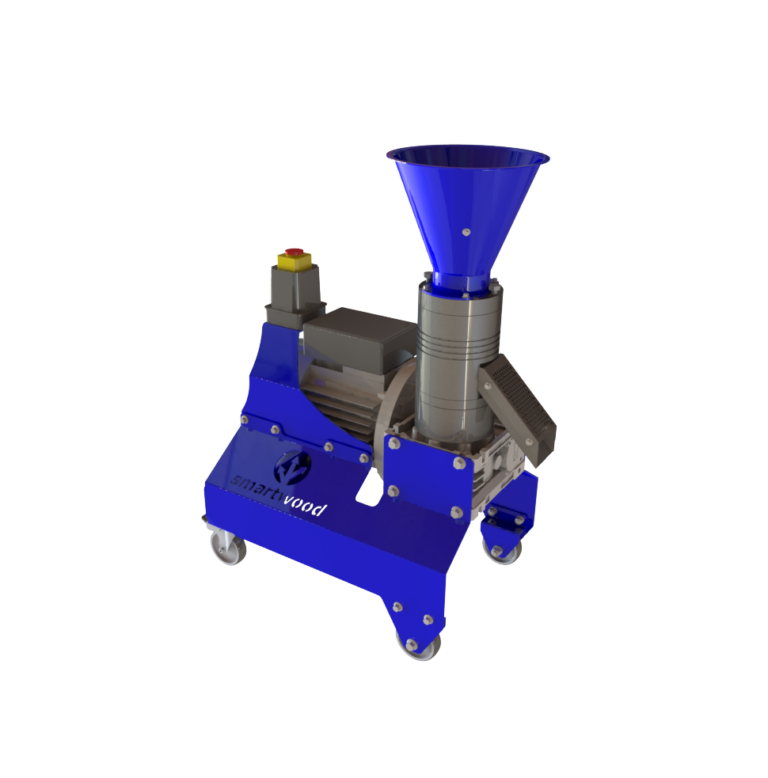

PLT-1000 – Compact, powerful, and professional

The PLT-1000 is Smartwood’s three-phase pellet mill designed for those who need a professional solution that combines high performance with compact dimensions. With 45 kW of installed power, it is ideal for industrial plants.

The machine is equipped with a 398 mm die (effective working diameter 360 mm) and 2 rollers of 180 mm, ensuring efficient and stable compaction. The standard die hole diameter is 6 mm, but other sizes are available upon request, depending on the material and final application.

The hourly output depends on the type of material being pelletized, but the PLT-1000 always guarantees continuous operation, consistent pellet quality, and maximum reliability.

Thanks to its compact footprint (181 x 96 x 152 cm) and weight of 950 kg, the PLT-1000 can be easily integrated into lines, offering an excellent balance between size and output capacity.

Typical applications

Smartwood pellet mills, including the PLT-1000, are designed to process a wide range of materials, including:

-

Virgin wood and wood waste (logs, sawdust, shavings, refined chips)

-

Straw and agricultural residues (corn stalks, hay, alfalfa, shells, husks, etc.)

-

Vegetal and organic residues (pruning waste, agro-industrial by-products)

-

Animal feed, for livestock or experimental use

-

Selected waste, for energy recovery or controlled recycling

For each material, we offer customized testing at our facility, allowing us to evaluate output, pellet quality, and machine suitability for your specific needs.