Although today it can be said that almost everyone has heard of it we consider it necessary to learn more about it since there are many circulating and discordant rumors...

First of all, it should be said that, in itself, the term does not identify an environmentally friendly alternative wood fuel as it is understood: in fact, this term indicates the cylindrical shape of a compact product of small size resembling a cork or bullet–this term has also been used for a compacting/densification process in the feed and agribusiness sector in general. In fact, pellets have existed as a result of this process for dozens of years and were created to meet the need for transportability, storability of feed for farm animals.

The correct term is “wood pellets,” and we owe its existence to the development of such technologies in the agribusiness and animal husbandry sectors.

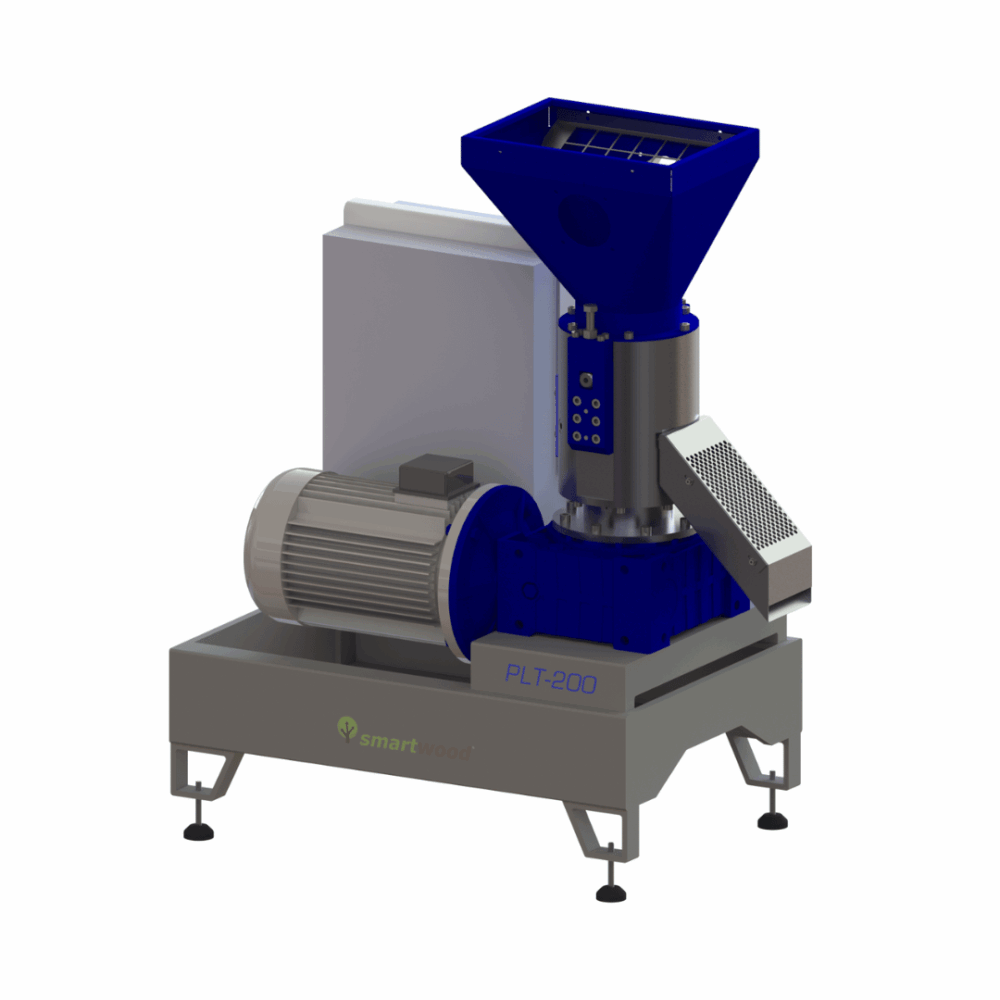

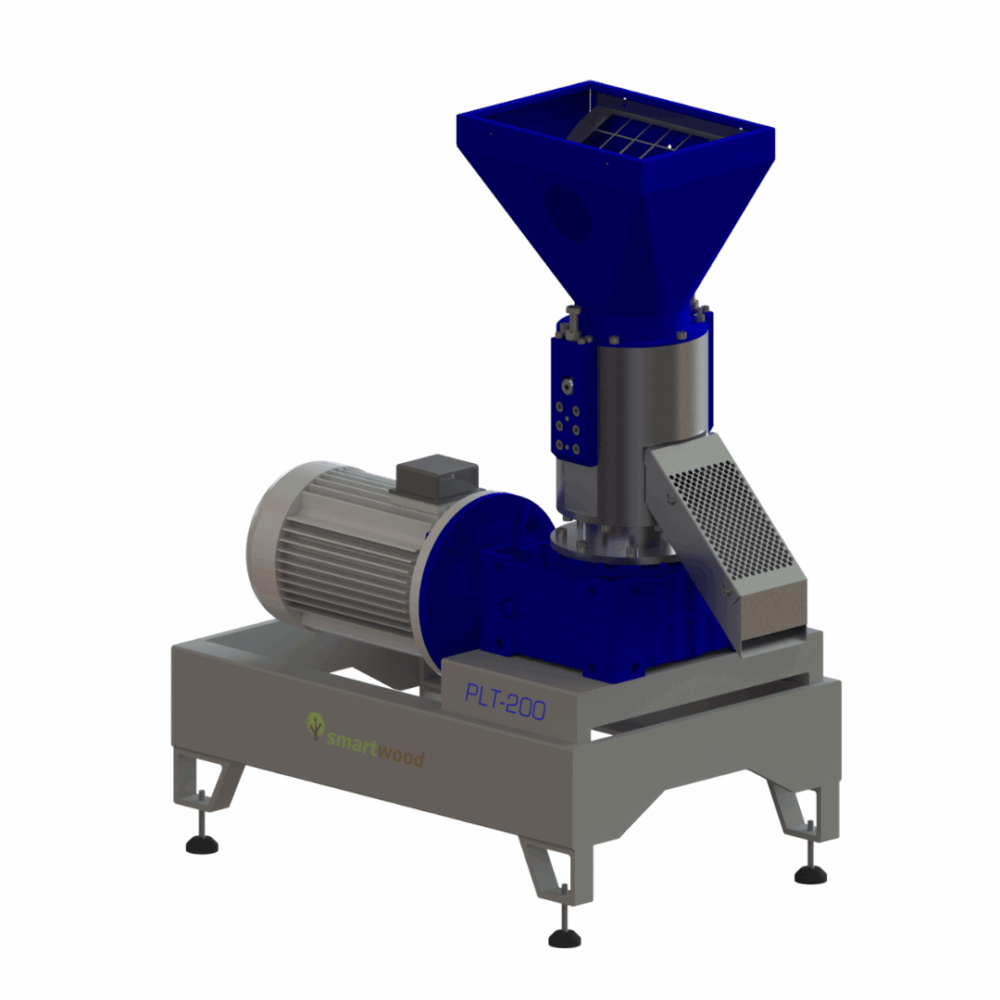

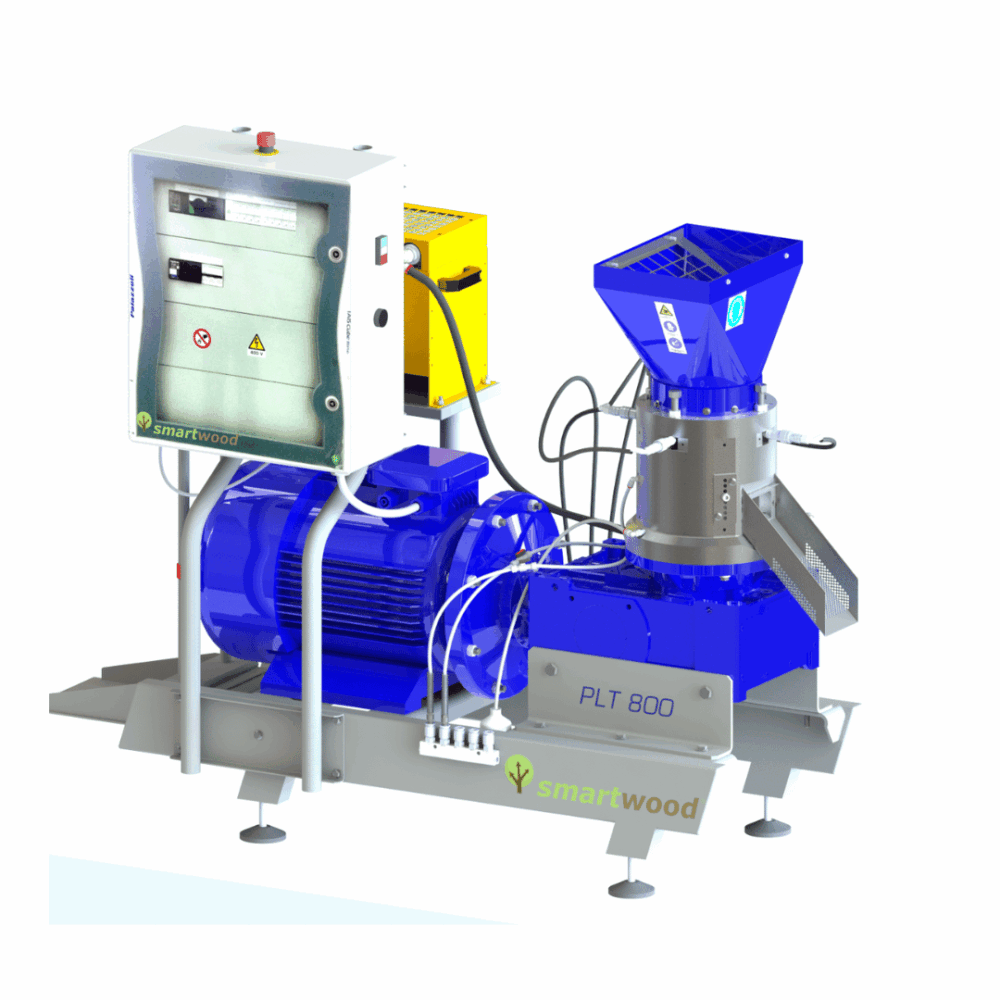

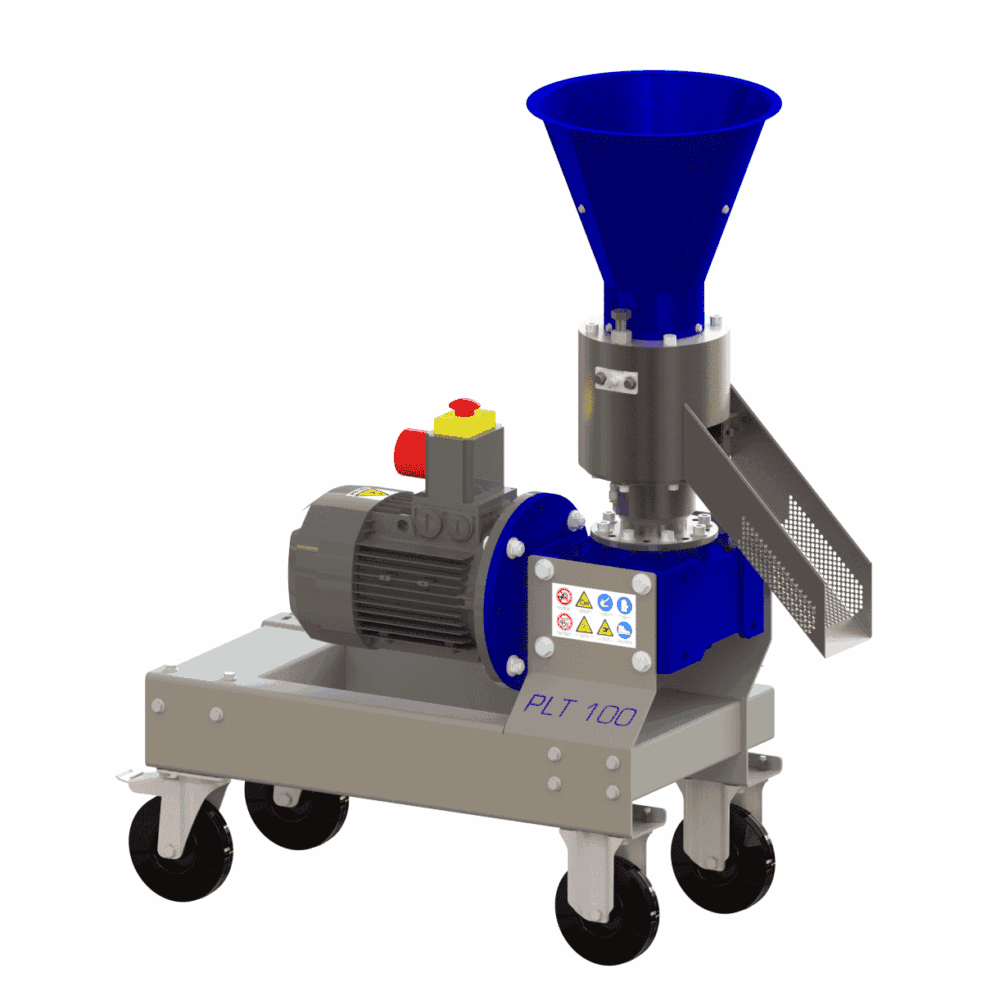

It would appear that Canadians were among the first to adopt the “pelleting” process in the feed industry as early as the 1960′s and then, from there, special machines were created to try to densify sawdust more as a waste product from processing logs and lumber in general (1980′s). However, it should be kept well in mind that the presses used to compress sawdust look very similar not to say identical to those for animal feed but in reality have quite different characteristics that also affect the entire production process; this remains to this day a red herring for those wishing to break into this production sector since this belief (and thus facilitation) has recently claimed many industry victims.

Some may ask why so much effort and strain when Mother Nature already provides us with the wood in the natural state we all know, with only the sacrifice of cutting.

The answer is articulated in multiple benefits that are in our view undeniable:

- First of all, the problem of waste disposal of sawmills and related companies that process large quantities of lumber and planking must be understood; sawdust is yes a natural material but when we are talking about huge quantities it becomes a real ecological problem of disposal not to mention the transportation and storage costs that companies have to bear.

- Derived from the previous utility, combustible wood pellets help to cut down fewer trees to produce firewood and is thus, for that reason alone, a double ecological benefit.

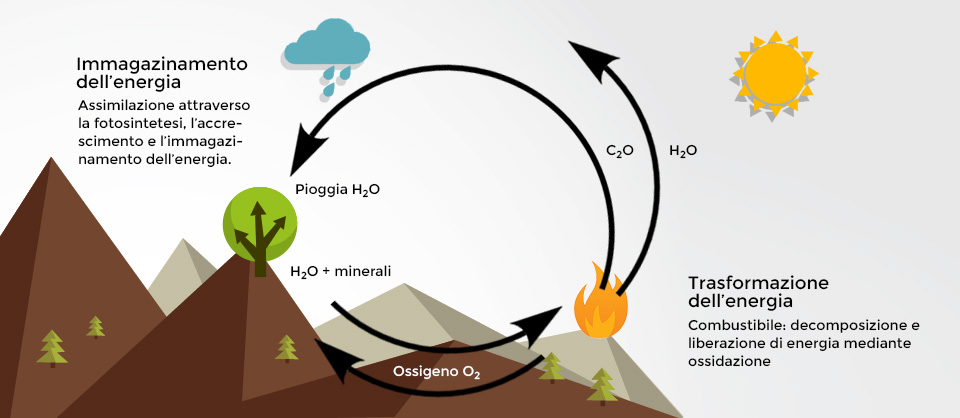

- The third ecological advantage is that its degree of pollution during combustion is the lowest ever; in addition to not damaging the ozone layer, and thus not aggravating the greenhouse effect since it is natural wood (and not fossil fuel), the appliances using it reach very high combustion regime temperatures under microprocessor electronic control: this always ensures a perfect oxidation process of the gases produced by the wood since a small "firmware" program constantly adjusts the amount of fuel and air needed for the combustion process. Something similar happened in the automotive industry with the advent of so-called lambda-probe catalytic converters.

- On the more practical and economic side, we have to think that users of firewood are probably the best candidates to give an answer. For while it is true that everyone cares about the huge savings on the cost of heating, it is equally true that most people do not accept the inconvenience of a woodshed in their home. Having a woodpile means a lot of occupied space, time to spend on it during the summer season for storage, "bustle" of baskets for stove/fireplace replenishment resulting in dirt and debris...in short, it's not for everyone. Due to its tiny, cylindrical and homogeneous shape, wood pellets behave much more like a liquid than a solid.The feeding of it into the appliances is automatic and is done by taking it from a tank of variable capacity, which allows for very long autonomies. Yearly storage is simple, convenient and quick: suffice it to say that the calorific value of a good stove pellet reaches as high as 4,400 Kcal/h per kilogram (PCI)* while firewood is normally around 2,500 Kcal/h per kg. Pellets then take up 1/5 the space of firewood and are also packaged in convenient 10-15 kg bags that are clean and easy to transport.

As an example, below is a fuel comparison table with pellets:

| Fuel type | Unit of measurement | Heat output (P.C.I.)* |

|---|---|---|

| Wood pellets | Kg | 4,400 Kcal/h approx. |

| Firewood | Kg | 2,500 Kcal/h approx. |

| Methane | Lt | 8,200 Kcal/h approx. |

| Diesel fuel (1 Lt=0.85 Kg.) | Kg | 8,500 Kcal/h approx. |

| G.P.L. (1 Mc=4.166 Lt.) | Mc | 21,500 Kcal/h approx. |

(P.C

(P.C.I.)* = Lower Calorific Value; that is, the calorific value that does not take into account the latent heat of evaporation of water : in practice, from the total energy released by combustion, that part necessary for the evaporation of the water contained within the fuel is rightly deducted. In the case of biomass, this part of energy is relevant and heavily conditioning the value of P.C.I.

It remains understood that the caloric value of wood has important variations depending on its seasoning and therefore water content. From the diagram above, it is easy to derive what the percentage of savings is compared to traditional fossil fuels: surely 50 percent is a more than reliable average figure, even considering the differences in prices according to areas. If we then consider heating by hot air (stoves, central air generators, etc.) in normal-sized housing and houses, we can reach peaks of 70%. As for the comparison with wood, and at its normal market price, we can say that we are on the same page, with some cases of further small savings.

Ashes and returns:

The other very important aspect of pellets is ash content: in fact, firewood not only has the problem of water content (<40%), which drastically lowers its calorific value, but also that of bark content and various impurities. Most good-quality pellets on the market offer ash contents of less than 1 percent of total weight and water contents of less than 10 percent; this means that the appliance that burns them (e.g., small stoves) will offer the user the possibility of greatly limiting its cleaning and refueling, making pellet burning something acceptable even for those who have always used liquid or gaseous fuels.

Alternatives to pellets:

For fairness and completeness of analysis, it is necessary to make a small comparison with a woody biomass fuel called “wood chips” (from English wood chips). Through the process of shredding/grinding the wood and its waste, a more or less uniform product is obtained, which also allows automatic feeding of boilers and various heat generators. To ns. Way of looking at it, the market for wood chips begins where the market for pellets ends and vice versa: in fact, wood chips still obliges larger automatic feeding systems because of its larger size; the water content, which is always high in any case, does not allow the use of simple and compact combustion chambers but often makes use of very expensive and complex technologies. In practice, regardless of the availability of fuel, the overall investment in woodchip combustion technology is significantly higher, making it uneconomical on small- to medium-sized plants; put simply, there is no point in paying very little for fuel if the small plant has very high depreciation costs.